What Are the Key Differences Between Parallel and Series Inverter Setups?

Defining Parallel and Series Inverter Setups

When you set up a solar system, how you connect inverters matters a lot. In a parallel setup, multiple inverters share the same power input and work together to make more current at the same voltage. In a series setup, inverters are linked one after another. They add up their voltages but keep the same current.

This difference changes how each setup works with different power needs. Parallel setups are great for giving lots of current. Series setups are better for making high voltage without extra current.

Common Applications in Industrial and Commercial Environments

Parallel inverters are super popular in places like data centers, telecom stations, and High-Frequency Modular UPS systems. These spots need flexible power and backup plans. Series inverters are used in special jobs, like sending power far away or for machines needing high voltage.

Inverters help power gadgets like laptops, phones, or small kitchen tools. Parallel setups are often used here because they’re easy to grow and handle changing power needs.

Importance of Configuration Choice in System Performance

Picking between parallel and series isn’t just about power. It affects how well your system saves energy, stays safe, handles problems, and grows later. A wrong choice can waste energy or cause the system to stop working when you need it most.

How Do Electrical Characteristics Affect Load Sharing?

Voltage and Current Output Differences Between Configurations

In a parallel setup, each inverter adds to the total current but keeps the voltage the same. This makes it easy to share power across devices. In a series setup, inverters add up their voltages, but the current stays the same. If one inverter breaks, the whole chain might stop working.

This makes parallel setups great for high-current needs and series setups better for high-voltage jobs.

Load Distribution Mechanisms in Parallel vs. Series Systems

Parallel systems are awesome at sharing power. They use smart tricks to figure out which inverter isn’t working hard and give it more to do. Series systems can’t do this. All inverters in a series setup carry the same current, so there’s no way to shift power around.

Smart systems in parallel setups adjust power in real time. This keeps everything running smoothly, even if the power need changes.

Impact on Power Quality and Stability

Parallel setups give cleaner power. They let each inverter fix small issues. SOROTEC’s inverters are super tough. They’ve been tested in lots of projects and stay steady in bad weather or long work hours. This makes them perfect for places like hospitals or computer centers.

How Does Each Configuration Support Scalability and Redundancy?

Expansion Capabilities with Parallel Inverters

Parallel setups are super easy to grow. You can add more inverters when you need more power without changing everything. SOROTEC’s hot-swappable modules make this even better. You can swap parts without turning off the system, which keeps things running.

This is great for High-Frequency Modular UPS systems that need to stay on and grow fast.

Limitations and Risks Associated with Series Connections

Series setups are trickier to grow. Adding a new inverter means fixing the whole chain to keep voltages even. This can make things unstable. If one inverter breaks, the whole system might stop unless you add special backup parts.

Fault Tolerance and Redundancy in Mission-Critical Systems

Parallel systems are awesome for backup. If one inverter stops, others keep going. This is super important for places like banks or hospitals where even a tiny break can cause big problems.

Series setups don’t have this backup unless you add extra parts. This makes them more expensive and harder to keep reliable.

What About Synchronization, Efficiency & Control?

Synchronization Requirements for Parallel Inverter Operation

For parallel inverters to work together, they need to match perfectly. Their power waves, speed, and strength must line up. If they don’t, bad currents can hurt the system.

SOROTEC uses smart controls to keep everything in sync. These controls fix things fast, even if the power changes suddenly.

Control Complexity in Series-Connected Systems

Series setups are simpler for syncing because there’s only one current path. But they have trouble keeping voltages even across all inverters. Small differences can mess things up, so you need fancy monitoring to fix it.

Efficiency Metrics Across Different Load Conditions

Parallel setups are better when power needs change. They use smart tricks to share work, so each inverter works just right. Series setups can waste energy because every inverter works hard, even if you don’t need all the power.

How Do Protection Strategies Differ Between Configurations?

Overload, Short Circuit, and Thermal Protection in Parallel Systems

Parallel systems are great at staying safe. Each inverter watches its own power, heat, and current. If something goes wrong, like a short circuit, it shuts itself off to protect the system. This keeps everything safe and makes fixing easy.

SOROTEC’s hot-swappable designs make it simple to replace broken parts without stopping the system.

Voltage Imbalance Risks in Series Configurations

In series setups, keeping voltages even is super important but hard. If one inverter has a different voltage, it can stress others and cause them to break. You need special parts to fix this, which adds cost.

Parallel setups don’t have this problem because they share current, not voltage.

Integration with Advanced Monitoring Systems

Both setups work with monitoring systems, but parallel ones give more details. Each inverter shares its own info, so you can spot problems early. This helps keep things running without breaks, especially in big systems.

SOROTEC’s systems use smart tech to watch everything and predict when parts might need fixing.

Which Configuration Is Best for Your Application?

Choosing the Right Topology for Data Centers, Telecom, and Energy Storage

If you have changing power needs, like in data centers or telecom stations, parallel setups are the way to go. They’re flexible and keep working if one part breaks. For special jobs needing high voltage, like some factory machines, a series setup might work better, but you need extra safety parts.

For energy storage, where you need both growth and reliability, SOROTEC’s Industrial Inverter Solutions are made for these tough jobs.

Performance Comparison Under Dynamic Load Conditions

When power needs go up and down, like with solar or wind power, parallel setups handle it better. They share work fast, so the system stays steady. Series setups struggle because they can’t change current easily. You might need extra parts, like big batteries, which cost more.

How Can You Optimize Design Using SOROTEC Solutions?

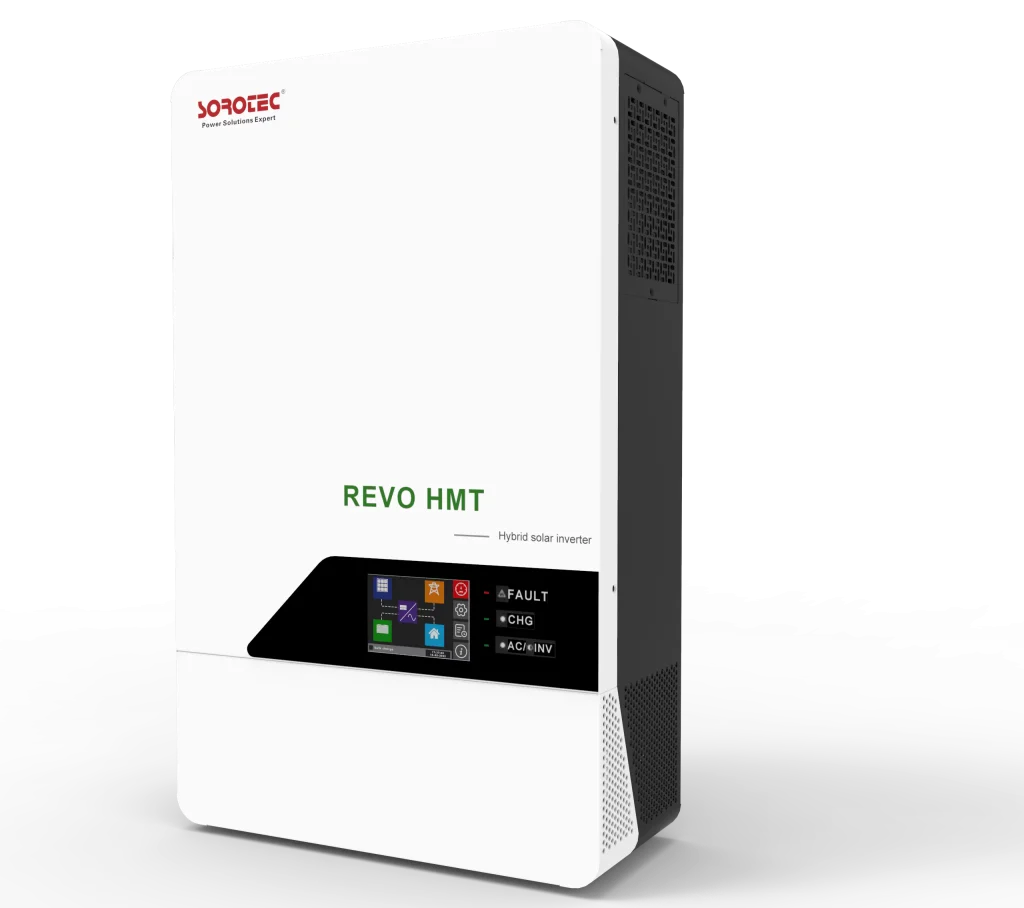

Introducing SOROTEC’s Advanced Inverter Technology

SOROTEC is a top company making awesome power tools for places like telecom and solar projects. Their inverters aren’t just regular—they’re super smart and built for real-world needs. With hot-swappable modules and clever controls, you get systems that stay on and work great.

Enhancing System Availability with SOROTEC’s Hot-Swappable Modules

Hot-swappable tech lets you fix or swap parts without turning off the system. This is a big deal for places like hospitals or banks where stopping power isn’t an option. SOROTEC’s designs make this super easy and keep things running smoothly.

Improving Load Handling Through Intelligent Parallel Management Features

SOROTEC’s smart controls keep all inverters working together perfectly. They adjust power in a snap, even if things get wild, like during power spikes. This makes sure you use energy wisely and keep things steady.

Customizing System Architecture with SOROTEC’s Flexible Configuration Options

Whether you’re adding to an old system or starting new, SOROTEC lets you build exactly what you need. Their designs fit any space or cooling needs, so you get a system that’s just right for your job.

FAQ

Q1: Can I mix different inverter capacities within a parallel configuration?

A: Yes, you can, but it’s best if the system has smart controls to balance things. Without them, different sizes might wear out some inverters faster.

Q2: Are there any safety concerns unique to series inverter connections?

A: Yes! Uneven voltages can cause big problems, like parts breaking or overheating. You need monitors to keep things safe.

Q3: Which configuration offers better long-term ROI?

A: For most jobs with changing power needs, parallel setups save more money. They’re easier to grow and break less, thanks to backup features.