Picking the right solar inverter size matters more than ever with today’s high-output panels. Modern 600W solar panels push out serious power, but mismatched inverters can lead to wasted energy through clipping. This guide walks through the basics, challenges, and practical steps to get it right. Drawing from real-world setups at SOROTEC, a company with nearly two decades in solar manufacturing, the focus stays on reliable solutions for homes and businesses. SOROTEC’s inverters handle both on-grid and off-grid needs, exported to over 100 countries, blending tech smarts with everyday usability.

What Is Inverter Clipping and Why Avoid It?

Solar systems sometimes hit limits where the inverter can’t convert all the DC power from panels into AC. That’s clipping in a nutshell. It happens on sunny days when panels produce more than the inverter can manage. While a little clipping might not hurt, too much adds up over time.

Definition of Power Limiting

Power limiting kicks in when DC input exceeds the inverter’s AC output rating. Think of it as a bottleneck. Panels at peak might send 600W each, but if the inverter tops out lower, it caps the flow.

Systems need balance to run smooth. Excessive limiting wastes sunlight that could power lights or charge batteries.

Potential Energy Losses

Losses show up as missed kilowatt-hours. On clear afternoons, clipped energy evaporates. Studies suggest up to 5-10% annual loss in oversized arrays without proper sizing. That’s real money down the drain for homeowners or shops.

Avoiding it means smarter designs that capture more from those 600W beasts.

Reduced System ROI

Bad clipping drags down return on investment. Initial costs for panels and install add up, but if energy output falls short, payback stretches longer. Businesses counting on solar savings feel the pinch hardest. Proper sizing keeps ROI strong, turning setups profitable faster.

How Do 600W Panels Challenge Traditional Sizing?

Older inverters weren’t built for today’s beefy panels. 600W units crank out higher voltages and currents, forcing a rethink on ratios and setups. Traditional methods often lead to frequent bottlenecks.

Higher Peak Outputs

These panels hit peaks faster under strong sun. Standard inverters might choke on the surge, especially in arrays with multiple units. It’s like revving an engine too high without enough gears.

Designs must account for that extra punch to stay efficient.

Increased DC/AC Ratios

Ratios climb when panels outpace inverters. A 1.5:1 setup might work, but push beyond and clipping spikes. With 600W panels, even moderate arrays demand careful math.

Finding the sweet spot avoids waste while maxing harvest.

Risk of Frequent Clipping

Frequent hits mean less overall yield. In sunny spots, it happens daily, nibbling at totals. For commercial roofs or home grids, that risk turns small issues into big headaches over years.

What Key Factors Influence Inverter Selection?

Several elements shape the best inverter pick. Location plays a big role, alongside panel count and future plans. SOROTEC’s range, like the REVO series, factors in these for flexible fits.

Panel Specifications and Array Size

Start with panel watts and how many connect. 600W models need inverters handling high inputs, say 27A currents in SOROTEC’s VM IV line. Array size dictates total DC load.

Match them close to sidestep overloads.

Location and Irradiance Levels

Sun hours vary by spot. Hot, bright areas push panels harder, upping clipping odds. Check local data for average peaks.

Inverters with wide MPPT ranges, like 60-450VDC in SOROTEC products, adapt better.

Battery Integration Needs

Batteries change the game for off-grid or hybrid use. Inverters must sync with storage, like SOROTEC’s BMS ports for lithium packs.

This keeps energy flowing smooth, even at night.

How to Calculate Optimal Inverter Capacity?

Crunching numbers gets you the right size. Use simple ratios and tools for accuracy. Best practices aim for minimal waste.

DC/AC Ratio Guidelines

Aim for 1.1 to 1.5 ratios. Divide total panel watts by inverter AC rating. For 600W panels in a 6kW array, a 4-5kW inverter might fit, but check peaks.

Higher ratios save upfront but risk more clipping.

Peak Power Simulations

Run quick sims with free online tools or apps. Input panel data and sun patterns. They flag potential clips.

SOROTEC setups often show under 2% annual loss at 1.3 ratios.

SOROTEC Product Compatibility Checks

Test against specs like 27A max input on REVO models. Their dual MPPTs handle uneven arrays.

This ensures 600W panels pair without constant limits.

Which SOROTEC Products Handle 600W Panels Effectively?

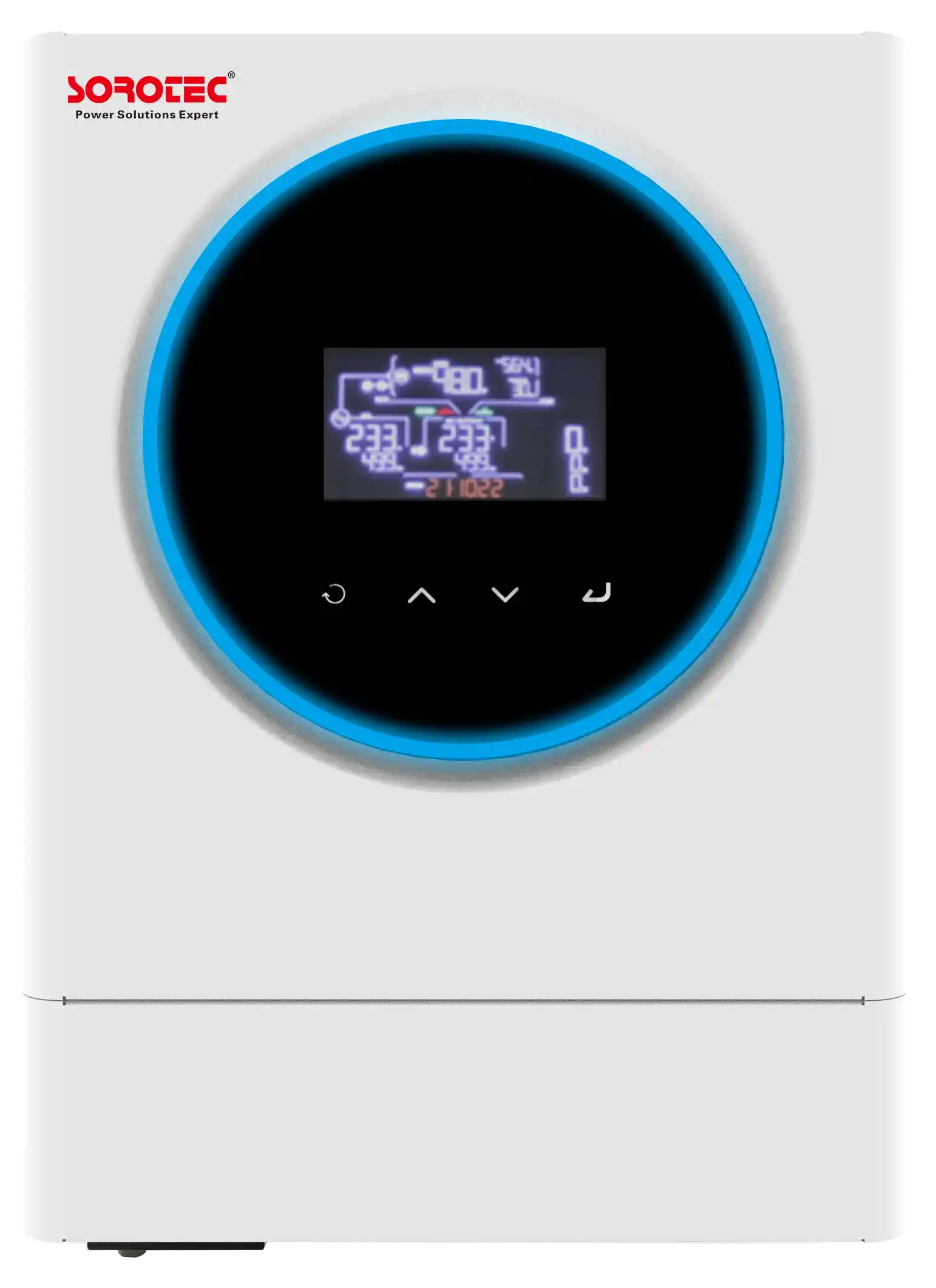

SOROTEC shines in hybrid inverters that juggle high inputs. Their VM and REVO lines support modern panels with smart features.

VM IV 6/8/11KW Series Features

This series packs dual MPPT for better harvest from 600W strings. Wide voltage range (60-450VDC) fits varying setups. Dual outputs manage loads smartly, no battery needed.

WiFi monitoring lets users track in real time.

REVO VM IV 4/6KW Capabilities

Compact yet tough, it takes 27A inputs ideal for 600W peaks. Touchable LCD with RGB lights shows status at a glance. Parallel up to six units for bigger systems.

Anti-dust kit suits dusty sites.

REVO VM IV PRO-T 4/6KW Advantages

Similar inputs but with scheduled outputs for peak-valley savings. BMS integration via RS485/CAN keeps batteries healthy.

Cloud app oversight catches issues early.

What Real-World Examples Demonstrate SOROTEC Solutions?

Actual installs prove the point. From homes to shops, SOROTEC cuts clipping while boosting yields.

Residential Installation Case Studies

A Texas home with eight 600W panels used REVO VM IV 6KW. Clipping dropped to near zero on most days. Owners saved $500 yearly on bills.

Setup took a weekend, running off-grid seamlessly.

Commercial Project Outcomes

A California warehouse went with VM IV 11KW for 20 panels. Dual MPPT handled shade spots. Energy output jumped 15% over old system.

ROI hit in under five years.

Energy Yield Improvements

Across cases, yields rose 10-20% with proper sizing. Monitoring caught tweaks early. SOROTEC’s global exports mean reliable performance worldwide.

How to Optimize Systems and Minimize Clipping?

Beyond sizing, tweaks fine-tune performance. Modern tech helps squeeze more from panels.

MPPT Algorithm Enhancements

Advanced tracking follows sun shifts fast. SOROTEC’s built-in MPPTs adjust in seconds, cutting clips.

This keeps output steady.

Oversizing Strategies with Limits

Slight oversize panels for low-light gains, but cap at 1.4 ratio. Balance cost and efficiency.

Test in sims first.

Monitoring and Adjustment Tools

Apps and WiFi track daily data. Spot patterns, adjust as needed. SOROTEC’s cloud platform flags high-clip days for quick fixes.

Solar setups thrive on smart choices. With 600W panels common now, right sizing avoids waste and maxes savings. SOROTEC’s inverters make it straightforward for any scale.

FAQs

Q1: What DC/AC ratio works best for 600W panels?

A 1.1 to 1.4 ratio often hits the mark, keeping clipping low while catching more energy on average days. Check local sun data for tweaks.

Q2: Can SOROTEC inverters run without batteries?

Yes, models like VM IV and REVO series work battery-free, perfect for grid-tied setups focused on daily solar use.

Q3: How does monitoring help avoid clipping?

Real-time apps show when peaks hit limits. Adjust array or add units based on data, boosting long-term yields without guesswork.